So after last weeks tutorial there was a little bit of a light bulb moment. I had all these grand schemes in my mind and it was brought to my attention that there is no way i can get this all done by myself. So in a turn of events, it seems i will only be designing one section of my grand scheme.

My big head has been forced to shrink a little and as such I'm left a little dis-allusioned. This does however allow me to take greater ownership of my design and the all important details that my design will consist of.

The component of my design that I will be taking greatest ownership of will be my 'nano pits', this is the waste processing component of the grand scheme. It will be residing WITHIN the boundaries of the existing Myer centre. This is the fuel that propels the new retail landscape of the future, these pits will disassemble and sort the waste of the residential component of the design (which i will not be designing).

The idea i have in my head is that these nano pits will be suspended in the existing voids of the Myer centre, they will create a visual connection between the new found industrialisation of the city centre and the borne again retail outlets. The pits in isolation cannot be an appropriate solution to the design challenges of the future scenario, the space the pits they need to be a mechanism, controlling, storing and reusing these waste materials for the purpose of manufacturing individuality of the new retail landscape.

I envision a transport system with fork lifts on tracks buzzing around the space through the void (visually connected to the retail interface) filling and carrying these 'filing' boxes of material through the space, to be stored on shelves through out, and obtained and used for the purpose of customised 3D printed products for the retail interface of the design.

The 'ground' plane, the voids that cut through the existing building, act as the public forum the stage where the future scenario plays out, encouraging voyeurism within the design.The exterior shell of the building is gone, a new skin envelopes the building facilitating the parasitic residential component of the design (which i will not be designing), the skin is 'alive' and responsive, reflecting the exterior inputs adjusting to suit the interior interventions.

Finally the parasitic residential component will sit on top of the existing voids opf the building, this will become the 'lift' shafts, vertical movement through the new and old will be implemented and additionally the nano pits will cascade through these shafts collecting and sorting facilitating the new sustainability closed loop system within the building.

Friday, 28 September 2012

Tuesday, 18 September 2012

Building technology

Investigation of nano technology and discussions in tutorials led to the idea of a 'nano-pit'. This would be an integrated component of the design for the building. The residential component of the design feeds the waste processing system. So the idea of the 'nano-pit' is that is will be the 'soul' of the building, it will sort the waste produced by residents and disassemble this waste into its base constituents so as to feed the manufacturing processes of the commercial side of the design.

This system ties in with what Yasu spoke about in the lecture of what sustainability is... it is not mass greening of the city it is the in depth consideration of the design of a product or building in how it will be used, reused or have its life prolonged. The aim to create a permanent, spontaneous design is enabled through the use of nanites. My building has the possibility of being 'alive', being both permanent and spontaneous in the response to its surrounds. The building grows organically in a parasitic manner on the Myer centre.

Monday, 17 September 2012

W8 Project developement

Product/ building lifecycle

Through consideration of my future scenario and my W7 project direction an interrelated life-cycle has been identified which will impact upon my design heavily. Driven by waste management and manufacturing, this cycle creates a future proposed closed loop system, it relies upon future peoples changed attitudes towards waste management and customisation. So the way i predict my future building to work is that people will consume, as they do today, they produce waste, as they do today, but here is where our future scenario kicks in, the people RECYCLE. So the people recycle, you might argue people have been recycling for a long time but this is different and this is where the new technologies kick in, nano-tech will sort and disassemble waste products into their constituent components to be recycled in the new manufacturing processes with all organic by-passes going into the vertical farming processes. All except the organic constituents feed the manufacturing processes, producing products which in turn feeds consumption, and so the cycle continues but in an economically and environmentally feesable manner.

Building function/ stacking

I have come up with the basic functions of my building. The design is aiming to integrate the above product/ building lifecycle through direct integration of the functions of the above lifecycle. So if the building provides a residence, a waste processing space, manufacturing space and a commercial 'retail' front the building in theory should become a self contained closed loop system.

Thursday, 13 September 2012

3D printing and manufacturing

So what does 3D printing mean for manufacturing in the future? Well 3D printers can build almost any 3D structure from supplied material, they will have the ability to build more complicated structures year by year and all you will need is a material and a digital 3D model to manufacture something from a 3D printer.

In our future scenario we considered a number of factors and as a result it was concluded that the resource crisis and societal attitude changes left people more inclined to 'live locally'. On-line shopping left retail spaces void in the future but as the city is the hub for the society, manufacturing moved in and replaced the void, bringing new life to the city centre.

Our proposed scenario is one were manufacturing of products is driven by intelligent design. Some one who manufactures products would be approached by a member of the public, commissioned to create a customised product which meets every requirement of the client. This ties in with the notion of extended product life cycle and peoples new found notion of waste management and conservation of resources.

References: http://techains.blogspot.com.au/2012/08/manufacturing-paradigm-shifts.html

http://www.engadget.com/2007/09/14/desktop-factorys-cheapo-3d-printer-is-coming/

In our future scenario we considered a number of factors and as a result it was concluded that the resource crisis and societal attitude changes left people more inclined to 'live locally'. On-line shopping left retail spaces void in the future but as the city is the hub for the society, manufacturing moved in and replaced the void, bringing new life to the city centre.

Our proposed scenario is one were manufacturing of products is driven by intelligent design. Some one who manufactures products would be approached by a member of the public, commissioned to create a customised product which meets every requirement of the client. This ties in with the notion of extended product life cycle and peoples new found notion of waste management and conservation of resources.

References: http://techains.blogspot.com.au/2012/08/manufacturing-paradigm-shifts.html

http://www.engadget.com/2007/09/14/desktop-factorys-cheapo-3d-printer-is-coming/

Wednesday, 12 September 2012

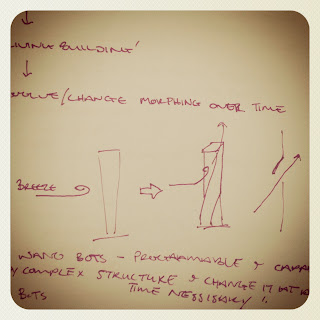

Nano technologies

In my research nano-technologies have become increasingly interesting to me. I have read about how a 'fog' of nano-bots could build any object or product for you, it could be used to create any 'reality' around you. This technology could also be used to reconfigure any structure and change the properties of different objects in an instant.

The appearance of programmable nano-bots, capable of building any complex structure and change it at any time necessary, opens a world of possibility in a number of areas such as production (manufacturing) and architecture to name the two I am most interested in.

When I apply this information to my investigation of our future scenario a lot of the ideas my group discussed can easily be intertwined and integrated with it. Nano-technologies could be applied to our idea of advanced waste management, we proposed that in our future scenario due to heightened resource scarcity there would be a societal attitude change towards waste management and consumption in general.

The technologies would allow for a sophisticated waste sorting system, nano-bots would sort our garbage, disassembling products into their base constituents which could then be utilised for the manufacturing of new products.

Or alternatively the nano-bots could be an 'input force' in the building. For example the only thing the nano-bots may do to the building is act as the component that as discussed earlier in this post, disassembles and reassembles the materials in the building to suit its surroundings. This is not intended to be used as a 'this building can have any function' draw card, I intend it to allow the facilitation of change but only in so far as to respond strictly to the functions of the building.

reference: http://techains.blogspot.com.au/2012/08/manufacturing-paradigm-shifts.html

http://inhabitat.com/tomorrows-skyscrapers-today-daekwon-parks-symbiotic-superstructure/

Tuesday, 11 September 2012

W7 Project Direction

As discussed, this project will be centring on localised manufacturing. In the first project a number of variables were identified guiding where the future will lead for the people of 2062, in the groups scenario we speculated that:

Project initiation occurs in the year 2030, with the design outcome being a form of parasitical architecture. The project will consider high tech solutions in regards to waste management and how that ties into localised manufacturing.

With the rise of on-line shopping and peoples economic hardship the 'death' of traditional retail was inevitable and because of the tax on embodied energy a shift towards localised production/ manufacturing became prevalent. Additionally due to the no cars in the city policy, public transport significantly improved quickly and the streets of the city were transformed into open public space for the people to reclaim and re-purpose for their own use. Finally due to increased resource scarcity, waste management becomes paramount to the people and they now recycle and reuse 90% of discarded products. Packaging is minimalised and products are made for the individual, customised specifically for their every need to ensure longevity.

The project will investigate how the city landscape has changed, how manufacturing has moved into the city scape and become an integral part of what attracts people to the city for work and for leisure. The project will deal with the issues of waste management, the manufacturing of products and how the manufacturing process responds to the demand for customisation.

The type of architecture will be mixed use, industrial and commercial space, the target users of the building will be workers and the public, the scale will be medium to large scale building.

- On-line shopping takes over the consumer market, 2017

- Introduction of a tax on embodied energy, 2023

- Public transport over haul, 2025

- In 2026, customisation is paramount

- Introduction of no cars in the city policy, 2027

- Waste management paramount, 2028

- The resource crisis peaks, 2030

Project initiation occurs in the year 2030, with the design outcome being a form of parasitical architecture. The project will consider high tech solutions in regards to waste management and how that ties into localised manufacturing.

With the rise of on-line shopping and peoples economic hardship the 'death' of traditional retail was inevitable and because of the tax on embodied energy a shift towards localised production/ manufacturing became prevalent. Additionally due to the no cars in the city policy, public transport significantly improved quickly and the streets of the city were transformed into open public space for the people to reclaim and re-purpose for their own use. Finally due to increased resource scarcity, waste management becomes paramount to the people and they now recycle and reuse 90% of discarded products. Packaging is minimalised and products are made for the individual, customised specifically for their every need to ensure longevity.

The project will investigate how the city landscape has changed, how manufacturing has moved into the city scape and become an integral part of what attracts people to the city for work and for leisure. The project will deal with the issues of waste management, the manufacturing of products and how the manufacturing process responds to the demand for customisation.

The type of architecture will be mixed use, industrial and commercial space, the target users of the building will be workers and the public, the scale will be medium to large scale building.

Monday, 10 September 2012

3D Printing... Human beings!

This is truly spectacular! The ability to grow bodily organs could mean a significant divergence in the way we function as a society from this time onwards. This sort of technology could see the introduction of on demand body organs, or even fully grown clones.

And with the ability to 3D print organs, will manufacturing in the future lead to 'printing' of bodies? Will they simply be a clone or will they in fact be their own individual being, living, breathing and thinking their own thoughts.

Will this new breed of clones become the working force of the future? Our 'robot' workforce to drive the growth of the future cities where education is paramount and 'professional' jobs are the larger proportion of positions, filling the void of the labouring force.

Subscribe to:

Comments (Atom)

.JPG)

.JPG)