Today, what we are faced with are faceless products, mass produced, all unchanging and the same. But this does not satisfy us. We crave products that suit us, ones that are specifically customised to meet our needs.

So in the future this is what we demand. Customised products that meet our needs specifically. But, this isn't enough to satisfy us though... we want to know where our products come from. Gone are the days of globalisation.

So Charlie wakes up of a morning, rising to products built for her, locally, with reduced embodied energy meeting her every need.

She checks her phone for the weather, it fits precisely in the palm of her hand. The phone matches her style, its sleek and thin, fits in her purse without bulging her custom built bag.

Charlie disposes of the phone when it no longer meets her needs. But what then happens to Charlies waste? Landfill? Not in the future, not anymore.

In the future, there is a closed loop system that has been adopted. New parasitical residential towers have invaded the city centre, and for this project more specifically the current Myer centre. These residents produce waste, we all do, even in the future... But at this point that is where the similarities between now and the future end when it comes to waste management.

Following waste disposal the materials go through a crushing process - a waste disassembly... followed by a sorting process to then be either be stored for future use or immediately be re-used in the manufacturing processes of the future retail enterprises. But how is this achieved?

Looking at the heart - the wonder of biological systems come into fruition. Our microscopic cells contract and pump our life sustaining blood through our body. It goes through filtration systems within the the body and recycles to keep us alive.

Even more fascinating is the lysosome, it contains enzymes that break down waste materials into their constituent components, which are in turn used to build new proteins.

Moving away from traditional industrial processes and approaches, bio - technology will advance and nano bots will be enlisted to fulfil and replicate biological processes.

Nano bots are so small they can rip atoms apart just like the lysosome. Breaks down the waste materials into their constituent components. The nano - pit adopts these biological processes to become the new solution to waste management in the future. The nano-pit pumps like a heart, and breaks down materials using nano bots to replicate the lysosome.

Coming down the inlet 'artery' there are protrusions which 'crush' waste to a smaller size, the pumping action sucks the material into the first chamber. Breaking down further through the use of bacteria, the waste then flows into the main chamber for the nano bots to disassemble to then be evacuated into the third chamber to be sorted and then released out of the outlet 'artery' of the nano - pit.

This newly broken down material needs to be moved and stored for future use in the manufacturing of new products on the retail front. Like in Wall-E I gained inspiration from how the robots ran on tracks in robot 'highways'. Additionally looking at wineries material storage was dealt with similarly, stacking the materials in containers for easy access to be moved to the 3D printers.

Once the robots have the newly broken down materials they move them to where they will be located with other resources of the same material types. They move both in the horizontal and vertical planes moving in the existing voids of the Myer centre up and down between levels.

The nano - pits occupy the existing voids of the myer centre hanging from the ceiling people occupying the building, as a shop owner or a customer, share a strong visual connection with the nano - pit.

Not only is it a functional aspect of the building in the future, it is a symbolic representation of how society has moved forward in its philosophies and how they wish to function as a society.

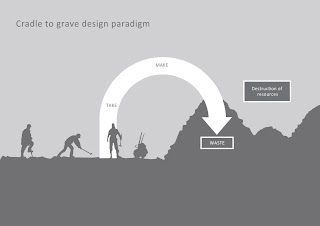

So today we act out the cradle to grave design paradigm. Taking what we want from the limited resources that are available, using them and then disposing of them. Next to no recycling occurs and if it is, it's not true recycling with most waste being left for decomposition taking hundreds if not thousands of years to be integrated into natural systems.

The future however, will rely on enacting the cradle to cradle design paradigm of the closed loop system - combing the biosphere and the techno-sphere's product life cycles to reach equilibrium in how we as a society manage waste.

So Charlie goes to the shop owner, an industrial designer, tells them just what she wants, a new product to match her every need. The designer then 3D prints the product for Charlie on the spot ready for use.

Charlie is in love with her new custom built product.

When this product no longer meets her needs she disposes of it.

The Future of waste management is the Nano - Pit, it is a functional solution as well as a symbolic representation of the societal changes in attitudes towards waste.

.JPG)

.JPG)